Industrial Digitalisation

As the UK’s National Measurement Institute (NMI), the National Physical Laboratory (NPL) must always consider the ways in which it can best support UK Industry. The global focus on digitalisation is thus one of the many areas in which NPL aims to identify and address measurement challenges, and as such, there has been continual growth in activities across NPL with digitalisation at their core.

A number of these activities fall under the Advanced Machinery and Productivity Initiative (AMPI), which is a collaborative initiative led by a consortium of both industrial and academic institutions to stimulate innovation and adoption of new technology through collaboration and direct support to industry. The initiative is funded by the UKRI Strength in Places Fund (SIPF) and includes both industry-led and academia-led research portfolios. Collaboration is ingrained in both portfolios to facilitate an innovation-led approach to benefit industry nationwide.

DMIMS Overview

The Dynamic Monitoring of Intelligent Machining Systems (DMIMS) project is one part of the academia-led research portfolio within AMPI. It is a five-year project being led by NPL which aims to address multiple measurement-related challenges within the context of machining systems. In broad terms, there are three focuses for the project, identified below:

- The development of quantifiably accurate, traceable, integrated sensor systems;

- The creation of generalised digital requirement specifications for integrating metrological process data and process-related metadata;

- Improvement upon the integration and automation of metrology on the production floor, with particular attention paid to interoperability.

Thematically, these focuses are incredibly close to one another, addressing the integration and development of machine process and metrology. In isolation, each could be its own project, but together they provide a compelling set of goals for this single five-year project which is intended to provide a springboard for further collaboration and innovation.

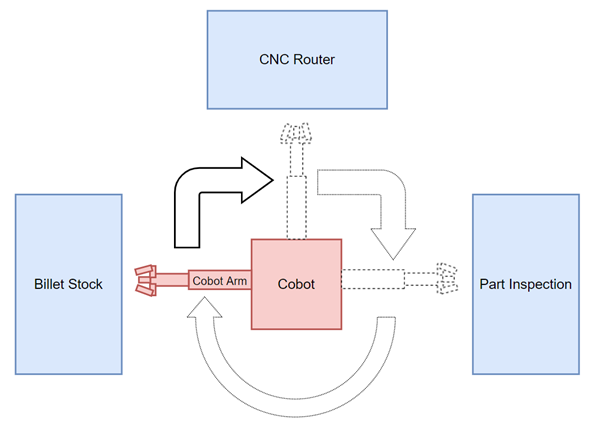

The initial phase of the project is a demonstration testbed for integrating peripheral sensing into a manufacturing process, or more specifically, the moving, making and measuring of a part. The process has two distinct stages: manufacture and inspection, which will be facilitated by a cobot as shown in Figure 1.

A billet of material is selected by a machine-vision-assisted cobot and placed inside the CNC router. The CNC router cuts the billet according to the digital CAD model. The cobot removes the billet from the CNC router and places it inside the part inspection solution, which performs dimensional measurements to enable comparison of the physical part to its CAD counterpart.

Whilst on-machine metrology research has been around for some time, the novelty of this project lies in its focus on the fusion of datasets from: on- and off-machine sensing systems; computer vision system(s); and the incorporation of machine learning techniques. This project is addressing the metrology of several systems in concert, as opposed to a single system.

Figure 1: Test bed schematic

Peripheral Sensing

The CNC router, part inspection solution and cobot, form the basis of the testbed and will each be supplemented with calibrated and traceable peripheral sensors to extract additional telemetry during each run. The goal of the test bed is to demonstrate traceable and accurate peripheral sensing which enables data-driven decision-making about the process. This will involve the creation of calibrated peripheral sensing using “standard” IoT infrastructure (such as off-the-shelf IoT sensing products), and the enhancement of machine data capture; supplementing data from the CNC router and part inspection solution with data from the peripheral sensing solution to improve confidence in the data.

We are incorporating a diverse range of technologies and sensing systems: from machine vision to real-time location sensing and low-power environmental monitoring. The lessons learned from fusing data from disparate and potentially asynchronous sources are as much an output of DMIMS as the data itself.

There are several challenges to be addressed in this part of the project, including the task of establishing a reliable way of synchronising machine data with peripheral data. Timestamping data is essential to performing meaningful analysis and implementing a common timing protocol is hindered by system components whose timing mechanisms are locked into ‘black-box’ software. In a similar vein, machine data is very often time-sensitive in an industrial setting, placing constraints on the practical elements of fusing live data from separate systems. There is also the subject of regulation to consider: any significant modification to a piece of equipment (such as a CNC router) carries the risk of altering its intended behaviour or affecting performance – which understandably invalidates regulatory markings such as CE and CA UK marks. Measuring the impact of modifications made during the course of the investigation is an ongoing part of the project.

Virtualisation

In parallel, a virtual model of the system is being developed. The creation of a virtual model provides the opportunity for several benefits such as iterative design improvement, virtualised quality and validation routines, and improved knowledge of the process itself. A virtual model also facilitates de-risked process improvement and optimisation. To create a useable model there must be a high degree of confidence in its accuracy, requiring quantified uncertainty and traceability of the data feed used to create it. Due to the nature of uncertainty propagation, it is critical that we obtain the best data practicable at the point of measurement, such that the usefulness of the data is maximised throughout its lifecycle: Figure 2.

Figure 2: Visualised data lifecycle and the propagation of uncertainty

Interoperability

Significant effort has been put into maximising the interoperability of our solution. We are using open-source resources where possible and practical, whilst recording the steps taken to integrate distinct components. Open-source solutions can be more difficult to implement, but the interoperability offered by open-source is often harder to realise with black-box or IP-locked solutions.

With the specific example of a peripheral sensing system, the value of a generic solution is of greater value to industry than a solution applicable to the products of a single vendor. Similarly, using standardised open-source frameworks and formats maximises the choices a data owner has when deciding what to do with their data, increasing the likelihood of a smoother integration with other parts of the supply chain, whether that is choosing a data storage vendor, a cloud computation platform, or wishing to migrate from one service to another. As such, the various open-source frameworks, tools and standards that already exist in a machining context are of interest to our project.

One way in which DMIMS incorporates interoperability is through the use of a Robot Operating System (ROS) network. ROS is an open-source robotics middleware that, whilst not technically an operating system, provides a set of software frameworks for developing software for robotics and robotics-adjacent applications. For the DMIMS testbed, it provides a useful messaging framework, a service provisioning and consumption protocol, as well as a well-documented foundation from which custom programs written in Python and C++ can be executed.

Summary

The initial phase of the DMIMS project is as much about producing an automated advanced manufacturing cell as it is about exploring and expanding upon the skills, techniques, resources, and technologies required to do so. By understanding the specific practical requirements of this kind of systems integration and development, a strong skills foundation is formed for future endeavours within the DMIMS project, as well as the wider initiative that is AMPI.

If you are interested in the topics discussed, would like some more information, or perhaps have an idea for a collaborative project, please feel free to contact me.

Daniel Povey – Higher Research Scientist

Manufacturing Metrology group