By Charlotte Blake, Trevor Toman, Phil Bamforth and Steff Smith

————

As manufacturing becomes increasingly reliant on digital technologies which require sharing of large amounts of data between different parties, the importance of metrology in validating data is growing rapidly. The metrologist is therefore emerging as a key role in data validation but for many years there has been poor recognition of that role both in terms of definition and in the establishment of career progression.

The Midlands Centre for Data-Driven Metrology (MCDDM) has recognised this as an important issue and, through a number of industry-focused events, is taking a lead on the development of a framework for metrology skills. Upon investigation by the Institute of Measurement and Control (Inst.MC), it was found that in the framework for engineering chartership, the words ‘measurement’ and ‘metrology’ do not appear in the document.

The development of the metrology framework is being led by Trevor Toman (Coventry University), Phil Bamforth (Rolls-Royce) Katie Blake (University of Nottingham) and Steff Smith (Institute of Measurement and Control). To ensure that this work is responding to the needs of industry, a group of companies who are willing to invest time to address this issue has been established as the National Metrology Skills Alliance (NMSA). Companies include Rolls-Royce, BAE-Systems, Reliance Precision, National Physical Laboratory, SuirFlo, Jaguar Land Rover, Sellafield and many more. Discussions held by this group have identified key areas of metrology needs in the manufacturing industry:

- Standardised skill sets to validate hiring practises for expert metrology roles

- Awareness of metrology practices for managers, design engineers and other non-metrologists to better understand the value of metrology in the manufacturing process chain

- Definitions of the competency requirements for different tasks and disciplines within the framework.

- Clear career development paths for metrologists

- An international standard that formalises the framework and competency requirements

- An assurance/accreditation process to enable:

- Demonstration of an internationally recognised level of competency and professionalism.

- Training providers to demonstrate consistent quality of their products to the standard.

- Organisations to have confidence when they recruit and train their staff.

As David Torr, Head of Metrology at Reliance Precision says: “At Reliance Precision, skills and competence play a leading role in the success of our business, none more so in the verification of product conformance. The subject of metrology plays a pivotal role in ensuring measurement processes are defined and fit for purpose – this means the competency of people working in the subject is vital. We wanted to be involved in the project to ensure that we, as a business, can contribute our knowledge of metrology so that the standard reflects how we approach metrology training – and what the important subjects are. We hope the standard helps with recruitment, internal training and evidencing our capability to our customers for the subject of metrology.”

In addition, a focus on ‘competency not certificates’ was highlighted as a priority area, to ensure that real-world skills and knowledge are valued within the framework. The importance of practical skills and the application of theoretical teaching has been strongly emphasised by hiring managers represented in the Alliance.

This year, the project has accelerated at pace and now a core steering group has been formed. This group, now formalised as a Special Interest Group (SIG) within the Inst.MC, is made up of representatives from large industrial organisations and manufacturing SMEs alike. Their goals for the framework, including plans for writing and delivery timelines for the standard were outlined in March. Three working groups of key manufacturing disciplines – Flow Metrology, Force Metrology and Dimensional Metrology – alongside a working group for a core framework underpinning all disciplines and the key capabilities required for this career path.

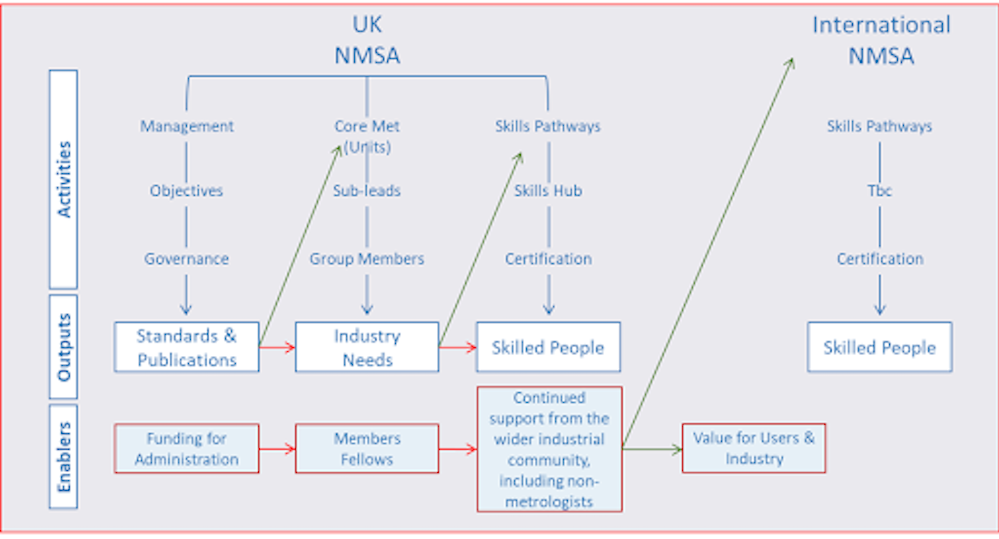

Image 1

Diagram outlining the structure of stakeholders and deliverables involved in and expected to contribute to the development of the standard Metrology training framework under development. Whilst the current project is UK-focused, the group are planning to expand internationally in the future as appropriate.

The first draft of competency frameworks is expected to be ready for delivery by September 2022. In this draft, the initial fields of Flow, Force and Dimensional Metrology will be trialled with a view to expanding to all other fields of Metrology in future iterations. The initial group of topics have been chosen for relevance to the manufacturing industry at large, in addition to the primary pull of users interested in the framework proposal; however, this list is not exhaustive and recommendations of additional areas for consideration are welcomed.

The Manufacturing group has now expanded with volunteer organisations and individuals from industry, developing the first draft populated with industrial needs and delivery solutions documentation, including methods and metrics for validation of skills, knowledge and competencies at different levels within the framework. To date, this has been set out as four work packages (see architecture diagram below). These organisations will be asked to stress-test the standard against their existing training schedule and hiring practices for metrologists in their company.

If you are interested in offering your time to this endeavour, please contact Prof. Trevor Toman at t.toman@coventry.ac.uk or Dr Phil Bamforth phillip.bamforth@rolls-royce.com for further information.

Diagram outlining the architecture of the training framework

Image 2

“Engineers of all disciplines are required to ‘measure’ and use aspects of ‘metrology’ whether Electrical, Mechanical, Chemical, Digital etc. Currently, there are adequate Standards to enable successful assessments of Engineers to award the appropriate Professional Qualifications. There is a body of Engineers who have the necessity to utilise detailed measurement knowledge from multiple disciplines, typically Flow Measurement Engineers, when adequate assessment proves difficult. A subject qualification covering ‘metrology’ could be utilised to assist in the assessment process and give a Professional Qualification status” – Gordon Fish, Director, SuirFlo Ltd.